PRODUCTION

PRODUCTION

Material Handled

We also produce Any Special metals as per Customer’s specification or International Standard Specifications like IS, ASTM, AISI, SAE, DIN, EN, JIS.

In general we handle regularly are listed below in table below :

- Carbon Steel : SAE - 1020, 1030, 1040, 4140, WCA, WCB, WCC, LCA, LCB,EN-9, EN-36

- Austenitic Stainless Steel : CF8, CF8M, CF3, CF3M, CF8C, CK-20, CN-7M (Alloy 20)

- Martensitic Stainless Steel : 410 (CA-15), 420 (CA-40), 431, 440C

- Duplex Stainless Steel : CD-4MCu, CD-4MCuN, CD3MCuN, CE3MN, CD3MN

- PH Stainless Steel : CB7Cu-1(17-4PH), CB7Cu-2(15-5PH)

- Super Alloys : HAST- B, HAST- C,HAST-B3, STELLITE-6, STELLITE-3, CZ-100, Monel

Wax Pattern Injection And Assembly

“Final casting quality is a mirror of the wax pattern Quality”

- We use Imported Pattern wax, and soluble wax for Accurate Pattern Making.

- Assembly Design is done to produce best yield with best quality.

- We have 05 Nos. of semi Automatic Wax Injection Press with Vertical injection, and Runner bar extrusion press.

Shelling & Dewaxing

The wax assembly is coated with a ceramic shell by repeated dipping in ceramic slurries and alternately in dry beds of sand and clays, heavy or thick sections are features of any part, additional coating is to give added strength to the shell. Thus eliminating bulging or distortion of the casting to complete this stage, the ceramic shell is heated under gas operated tank and the wax is removed by melting, leaving a hollow shell. The most crucial stage of the shelling process is the primary coating, where a very fine grade of sand is used. This in turn results in a casting with excellent reproduction detail and the designated surface finish.

Melting

- Our melting shop is equipped with Inductotherm make induction furnace with 300 and 150 Kg. Crucibles and temperature controlled Shell Baking furnace.

- We use standard and best quality scrape to ensure best metallurgical quality of Investment Casting products.

Fettling

- Our fettling shop is equipped with Shot and Sand Blasting Machines, Abrasive Cutting Machine, Belt grinder, Welding and other machineries necessary for the fettling.

- We are also doing Electroplating and other plating and coating as per requirement.

- We supply the casting without any gate and riser pads.

Heat Treatment

“To ensure desired material properties.”

- We are doing heat treatment like Solution annealing, Normalizing, Tempering, with temperature controlled Electric Heat Treatment Furnace along with special requirement of customers.

- Best Heat treatment practice is ensured by the microstructure study after heat treatment.

Final Inspection

- All castings are subject to 100% visual inspection.

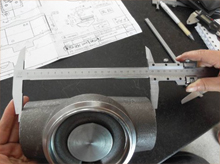

- All critical dimensions are 100% inspected before packing and final shipment.

Packing

- We are always taking care of finish products Delivery.

- We use standard Sea worthy wooden pallets and Corrugated boxes for Domestic and export packing.

OUT SOURCE PROCESS

Die Making & Inspection

We have all the facility and experience for the die making on VMC M/C for any kind of critical Components and We are doing 100% Die Dimension Inspection as per drawing before Sampling.